MULTIMEDIA: VIDEOS, PHOTOS, FACILITY TOUR

See, listen and tour to find out more about PPI’s capabilities that can help you.

Capabilities VIDEO

An in depth presentation of PPI's extensive capabilities is presented in this 9 minute video. View by selecting a clip. It is recommended to view these video clips in order 1-7.

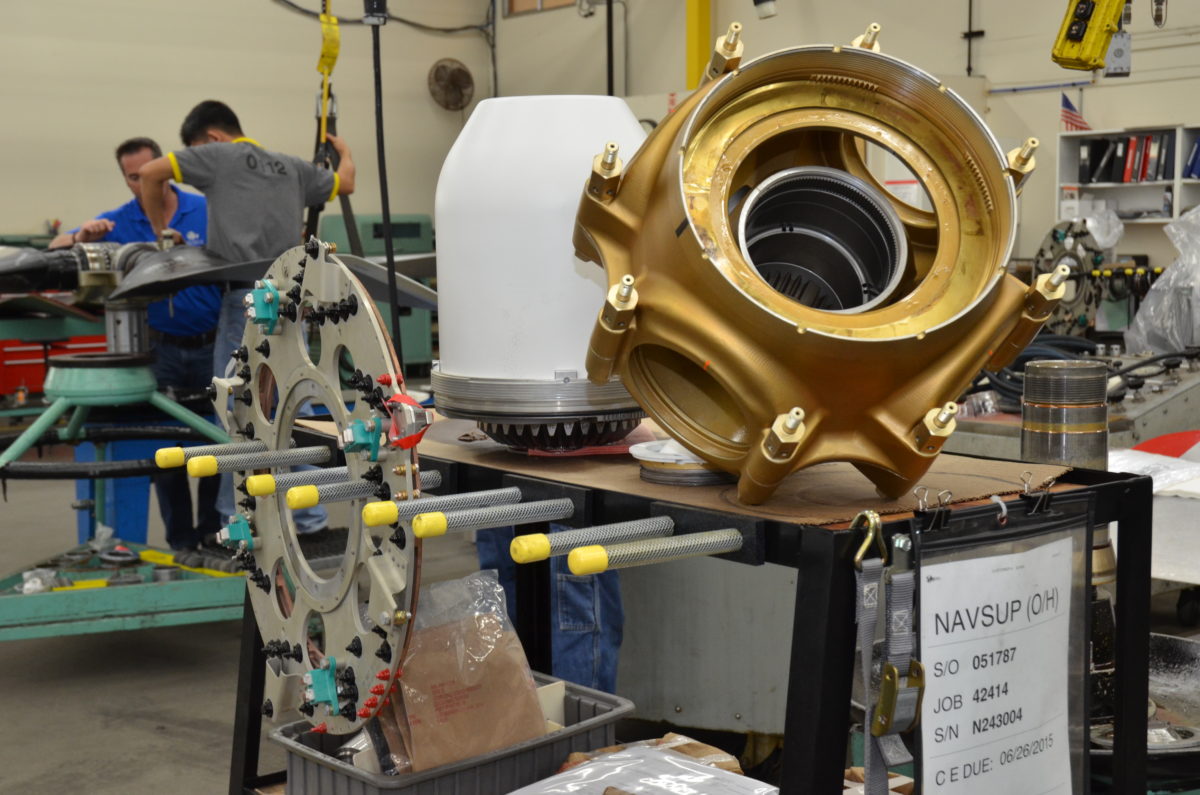

Capabilities PHOTOS

See some of the images of PPI's skilled technicians perform repairs and overhaul on a vast array of propellers and aircraft equipment.

The PPI Facility

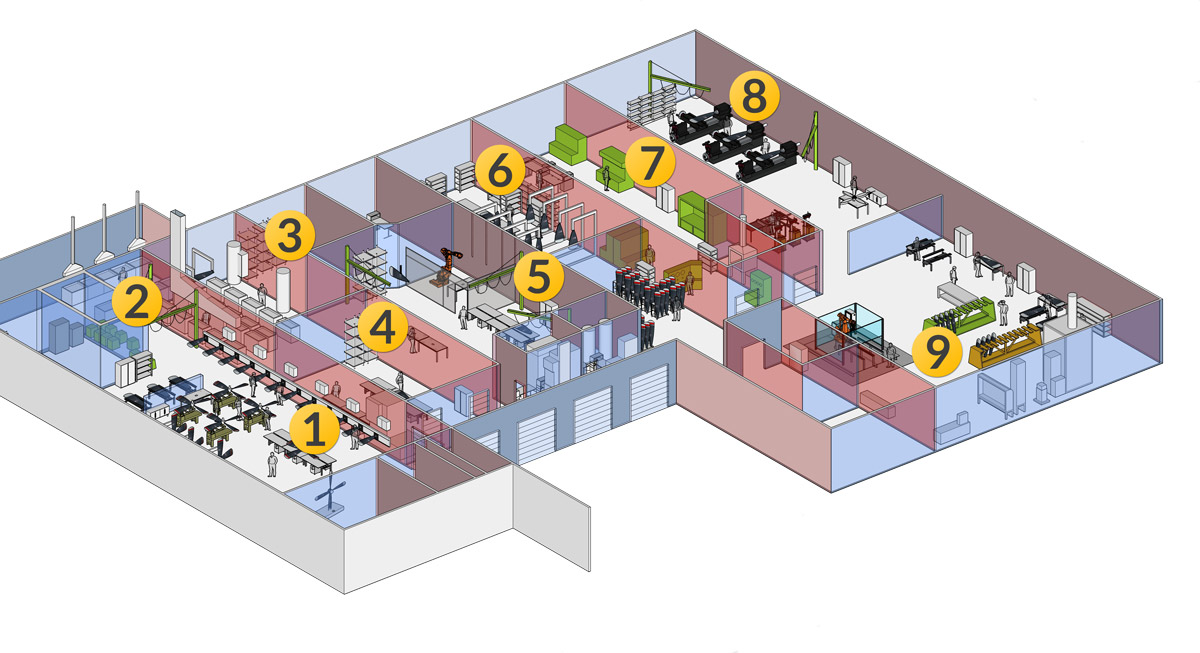

PPI’s 64,000 square foot facility provides overhaul and repair service to regional airline aircraft, agricultural aircraft and larger propeller aircraft. Different areas of the facility are devoted to different aircraft and overhaul processes.

In Large Propeller assembly propellers are tested and functionally ched through their full range of operation.

In Large Propeller assembly propellers are tested and functionally ched through their full range of operation.

PPI is unique in maintaining a complete anodizing and plating facility for aluminum blades providing extra protection from corrosion and erosion.

Following a thorough cleaning, blades are inspected using non-destructive testing and inspection techniques, uncovering even the smallest damage or defect.

Blades are ground and polished, removing any remaining imperfections to the blade surface. The “sleeve set babbit repair” process also occurs here.

Propeller control units are evaluated to determine the failure cause, repaired and made ready for testing.

Propeller control units are tested utilizing certified equipment that simulates the operation on the aircraft.

The machine shop specializes in repeairs such as the “fillet cut” and “cold roll” processes that remove wear and strengthen the C-130 & P-3 propeller blades.

Regional propellers as operated on the Dash 8, ATR & EMB 120 aircraft, are inspected, repaired, and tested utilizing the latest technology.