SPECIAL PROPRIETARY PROCESSES

SPECIAL PROPRIETARY PROCESSES

IN-HOUSE CAPABILITIES

IN-HOUSE CAPABILITIES

METAL RE-WORK

- Thrust Ring Grinding

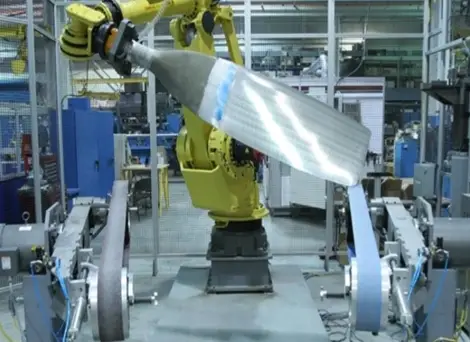

- Automated Shotpeen

- Automated Blade Grind

- Blade Fillet Cut and Cold Roll

- 54H60-77 (7121) Blade Manufacturing

- Taperbore Reaming

PLATING

- Cadmium

- Nickel-Chrome

- Anodizing

- Phosphate

- Copper

- Etching

NON DESTRUCTIVE TESTING (NDT)

- Fluorescent Penetrant Inspection

- Magnetic Particle Inspection

- Eddy Current Testing

- Ultrasonic inspection

54H60 PROPELLER SERVICES

54H60 PROPELLER SERVICES

BLADE REPAIR & OVERHAUL

- Blade Bushing Screw

- Hole Repair

- Taperbore permatreat

SUBASSEMBLY REPAIR & OVERHAUL

- Low Pitch Stop

- Pitchlock Regulator

- Dome • Contact Ring

- Bulkheads

- Mounting Brackets

- Spinners

CUFF RE-WORK

- Foam Cuff Pour

- Boot Replacement

- Contact Rings

- Teflon Seals

- Blade Heaters

INTEGRAL OIL CONTROL (IOC)

- Valve Housing Repair & Overhaul

- Pump Housing Repair & Overhaul

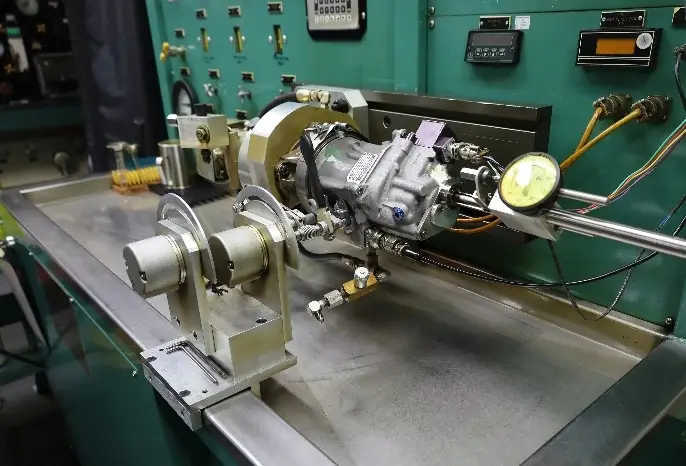

- Full Testing Capability

- Syncrophazer Repair

PROPELLER CONTROL UNIT

PROPELLER CONTROL UNIT

OUR PCU SERVICES

- Repairs & Overhaul

- Modifications

- Major and Minor Inspections

- Full Testing Capability

CERTIFIED & WARRANTIED

- Full SB/AD Compliant

- FAA, EASA, AS9100 Certified

- 12- month Warranty

AERO PROPELLERS

AERO PROPELLERS

Pacific Propeller International is recognized as a leader in Maintenance, Repair, and Overhaul (MRO) services for the propeller systems of the Lockheed Electra L188 and Convair 580 aircraft. Specifically, we are the Original Equipment Manufacturer (OEM) for the A6441FN-606 propeller system used on these aircraft.

Our commitment to the Convair 580 and Electra L188 extends beyond general MRO. As the OEM for this propeller system, we have a deep understanding of its original design and ongoing maintenance requirements. This specialized knowledge, coupled with our extensive experience and certifications, positions us as a primary provider of MRO services for the propeller systems of these aircraft.

LOCKHEED P-3 ORION

Country of origin: United States

Passengers: 11

Engine: 4 x T-56 turboprops

Span: 99 ft 8 in (30.38 m)

Length: 116 ft 10 in (35.61 m)

Speed: 377 mph (607km/h)

Range: 1,548 mi (2,491 km)

Propeller Model No. 54H60-77

Spinner, P/N 549427

Control, P/N’s 597946, 739000-()

Valve Housing, P/N’s 710085-(), 582945

Pump Housing, P/N’s 727785-(), 582434

Synchrophaser, P/N 585500

LOCKHEED C-130 HERCULES

Country of origin: USA

Passengers: 92

Engine: 4 x T-56 turboprops

Span: 132 ft 7 in (40.41 m)

Length: 97 ft 9 in (29.79 m)

Speed: 336 mph (541 km/h)

Range: 2,360 mi (3,800 km)

Propeller Model No. 54H60-117/91

Spinner, P/N’s 704175-(), 557615

Control, P/N’s 714326-(), 577888

Valve Housing, P/N’s 714325-(), 582855

Pump Housing, P/N’s 733872-(), 582840

Synchrophaser, P/N 588584

Synchrophaser & Adapter, P/N’s 766840-(), 774800-()

Brakes, P/N 9560685, 9560685-1

LOCKHEED L-188 ELECTRA

Country of origin: USA

Passengers: 98

Engine: 4 x Allison 501 turboprops

Span: 99 ft 0 in (30.18 m)

Length: 104 ft 6 in (31.85 m)

Speed: 373 mph (600 km/h)

Range: 2,200 mi (3,500 km)

Propeller Assembly No.6505849

Hub Assembly No.6859444

Blade Model, P/N 6851614

Regulator Assembly, P/N 6505680

Spinner, P/N 6505883

Reservoir, P/N 6503835

Phase Synchronizer Module, P/N 6508977

Phase Sync, (606), P/N 6504719

Synchronizer, P/N 6504717

CONVAIR 580

Passengers: 56

Engine: 2 x Allison or 2 x Dart turboprops

Span: 91 ft 9 in (27.97 m)

Length: 74 ft 8 in (22.76 m)

Speed: 280 mph (450 km/h)

Range: 1,200 mi (1,900 km)

Aero Propeller Model No. A6441FN-606

Propeller Assembly No.6505849

Hub Assembly No.6859444

Blade Model, P/N 6851614

Regulator Assembly, P/N 6505680

Spinner, P/N 6505883

Reservoir, P/N 6503835

Phase Synchronizer Module, P/N 6508977

Phase Sync, P/N 6506594

ATR 42

Passengers: 48

Engine: 2 x PW12X

Span: 80 ft 7 in (24.57 m)

Length: 74 ft 5 in (22.67 m)

Speed: 333 mph (535 km/h)

Range: 780 mi (1,260 km)

Propeller Model No. 14SF-5

PCU Model No. 782490-51

ATR 72

Passengers: 72

Engine: 2 x PW127M/N/XT

Span: 88 ft 9 in (27.05 m)

Length: 89 ft 2 in (27.17 m)

Speed: 317 mph (510 km/h)

Range: 872 mi (1,404 km)

Propeller Model No. 14SF-11

PCU Model No. 782490-51

CANADAIR CL 215

Passengers: 26

Engine: 2x 2,200 hp Pratt & Whitney R-2800-83AM

Span: 28.6m

Length: 19.82m

Speed: 290km/h

Range: 2,094 km

Propeller Model No. 14SF-17, 14SF-19

PCU Model No. 782490-48

CASA 235

Passengers: 26

Engine: 2x TPE331 Turboprops

Span: 19m

Length: 15.16m

Speed: 347km/h

Range: 370

Propeller Model No. 14RF-21,14RF-37

PCU Model No. 782490-49,782490-57

DE HAVILLAND DASH 8

Passengers: 37-90

Engine: 2 x PW123/150

Span: 93 ft 3 in (28.4 m)

Length: 107 ft 9 in (32.8 m)

Speed: 350-410 mph (300 – 360 kn)

Range: 1,300 mi (2,040 km)

Propeller Model Nos. 14SF-15 ,14SF-7, 14SF-23

PCU Model Nos. 782490-47, 782490-50

EMBRAER 120

Passengers: 23-30

Engine: 2xPW115 turboprops (Pratt & Whitney PT6D-200)

Span: 19.78m

Length: 20m

Speed: 487 km/h

Range: 1112 km

Propeller Model No. 14RF-9

PCU Model No. 782490-46

SAAB 340B

Passengers: 34

Engine: 2xCT7 turboprops

Span: 21.44m

Length: 19.72m

Speed: 467km

Range: 1795 km

Propeller Model No. 14RF-19

PCU Model No. 782490-52 ,782490-55 ,782490-56